What advanced device utilizes laser

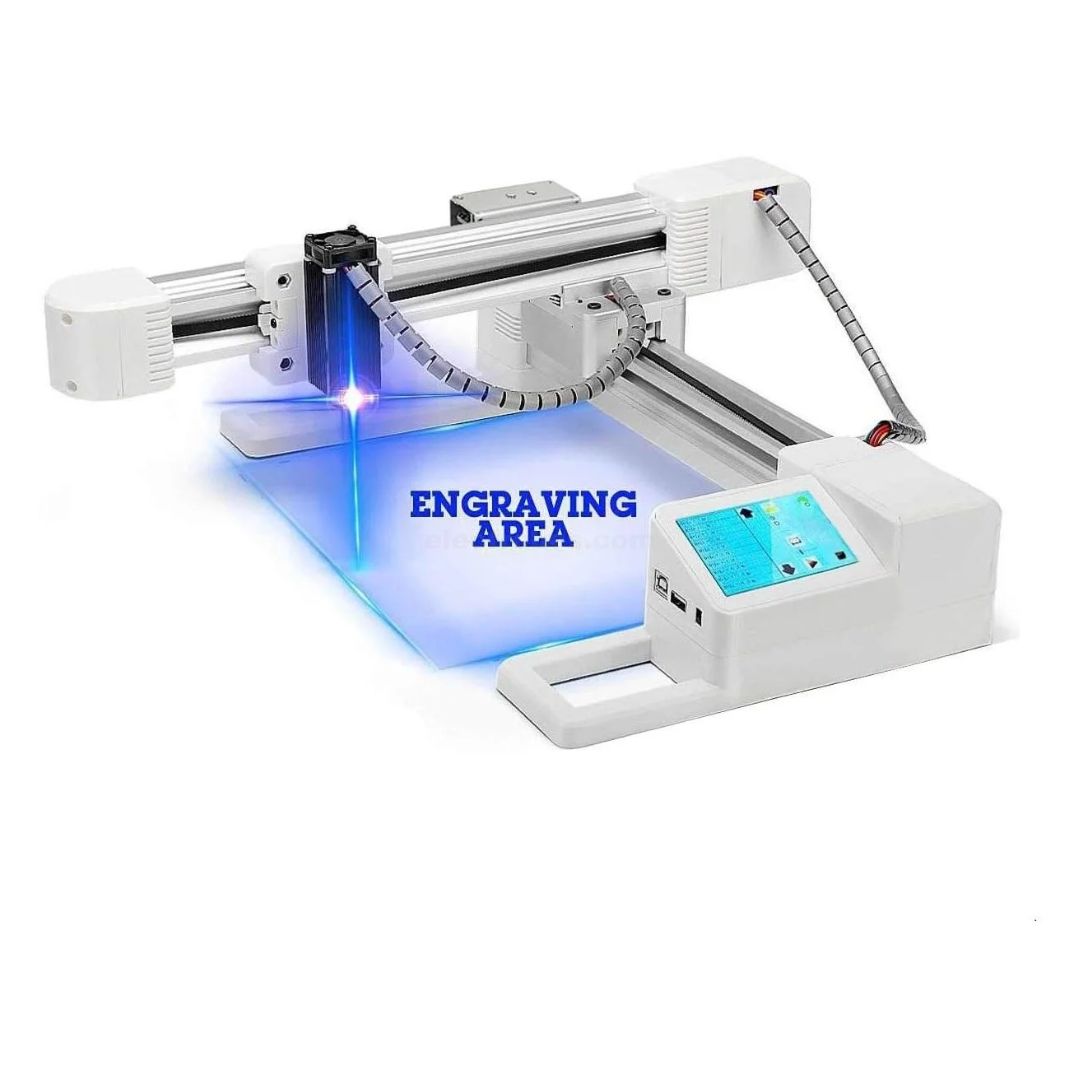

In the modern landscape of artistry and manufacturing, the laser engraving machine stands out as a pivotal tool that merges technology with creativity. This innovative device allows users to produce intricate designs, patterns, and text on a variety of materials. Whether you are a seasoned professional, a small business owner, or a hobbyist, understanding the capabilities and applications of a laser engraving machine can greatly enhance your creative projects. This article delves into the intricacies of laser engraving machines, their applications, and the essential considerations for those interested in utilizing this powerful technology.

What is a Laser Engraving Machine?

A laser engraving machine is a device that employs high-intensity laser beams to engrave or cut materials with exceptional precision. The process involves focusing a laser beam onto the surface of the material, which can vaporize or melt away the material to create designs. This method allows for a level of detail that is often difficult or impossible to achieve with traditional engraving techniques.

- The Technology Behind Laser Engraving:

- The core function of a laser engraving machine is to generate a concentrated beam of light that can be directed onto various materials. The laser’s energy interacts with the material, resulting in either a change of color or the complete removal of material along the designated path. This process is controlled digitally, allowing for intricate designs and consistent results.

- Types of Laser Engraving Machines:

- There are several types of laser engraving machines available, each optimized for different applications. Common types include CO2 laser engravers, ideal for non-metal materials, and fiber laser engravers, which excel in etching metals. Each machine operates at specific wavelengths and power levels suited to its intended use.

Applications of Laser Engraving Machines

The versatility of laser engraving machines enables them to be utilized across various industries and creative fields. Here are some notable applications:

- Art and Design:

- Artists use laser engraving machines to create intricate artworks and personalized items. The technology allows for the engraving of detailed designs on materials such as wood, acrylic, and leather, enabling artists to explore complex patterns and textures.

- Personalized Products:

- The ability to customize products is a significant advantage of laser engraving machines. Businesses often use them to engrave names, dates, and logos on gifts, awards, and promotional items. This personal touch adds value and appeal to products, making them more marketable.

- Industrial Marking:

- In various industrial sectors, laser engraving machines are employed for marking components with serial numbers, barcodes, and logos. This practice ensures traceability and compliance with industry standards, which is crucial for quality control.

- Jewelry Making:

- Jewelers utilize laser engraving machines to etch intricate designs on metals, enhancing the uniqueness of each piece. The precision of laser technology allows for fine details that elevate the overall aesthetic of the jewelry.

- Prototyping:

- Laser engraving machines are invaluable in the prototyping phase of product development. Designers can quickly create models and prototypes for testing, enabling rapid iteration and refinement.

- Memorial Products:

- The engraving of memorials, plaques, and keepsakes is another important application. Laser engraving machines can create lasting tributes by etching personal messages and images on materials such as stone or metal.

- Educational Tools:

- In educational settings, laser engraving machines can be used to create teaching aids and customized materials that enhance learning experiences. This technology allows for the production of engaging and interactive educational tools.

Key Considerations When Purchasing a Laser Engraving Machine

Investing in a laser engraving machine requires careful consideration to ensure that the chosen device meets your specific needs. Here are some important factors to keep in mind:

- Material Compatibility:

- It is crucial to select a laser engraving machine that is compatible with the materials you intend to work with. Different machines excel with different surfaces, so understanding your primary materials will guide your choice.

- Work Area Size:

- The size of the work area on the laser engraving machine should accommodate your largest projects. Machines come in various sizes, from compact desktop models for small tasks to larger industrial machines for extensive projects.

- Resolution and Speed:

- The engraving resolution affects the level of detail you can achieve, while the speed of the machine impacts productivity. Assess your project requirements to find the right balance between these factors.

- Software Compatibility:

- Look for laser engraving machines that are compatible with industry-standard design software. User-friendly software can significantly enhance the engraving experience and simplify the design process.

- Safety Features:

- Safety is an important consideration when using laser engraving machines. Ensure that the equipment includes safety features such as emergency stops and protective enclosures to protect operators during use.

- Budget:

- Laser engraving machines come at various price points, from entry-level options to high-end models. Establishing a budget that aligns with your needs and future potential for growth will help you make an informed decision.

The Future of Laser Engraving Technology

As technology continues to develop, the future of laser engraving machines holds exciting possibilities:

- Technological Advancements:

- Ongoing advancements in laser technology will likely lead to more efficient and powerful engraving systems. Innovations in laser sources, optics, and control systems will enhance the capabilities of these machines.

- Integration with Automation:

- The integration of laser engraving machines with automated processes is becoming more prevalent. Automated systems can operate with minimal human intervention, increasing productivity and ensuring consistent results across all pieces.

- Sustainability Initiatives:

- With growing emphasis on sustainability, laser engraving technology is expected to evolve to incorporate eco-friendly practices. This includes reducing energy consumption and waste during the engraving process.

- Wider Accessibility:

- As laser engraving technology becomes more affordable and user-friendly, it is expected to gain wider adoption among hobbyists and small businesses. This democratization of technology will empower more individuals to explore their creativity.

- Customization Opportunities:

- The demand for personalized products continues to rise. Laser engraving machines will play a crucial role in meeting this demand, enabling businesses to offer tailored solutions that resonate with customers.

Final Thoughts

Laser engraving machines are powerful tools that blend artistry with technology, enabling users to create intricate designs and personalized products with ease. Their applications span numerous industries, making them invaluable assets for professionals and hobbyists alike.

As you explore the world of laser engraving, consider the various factors that contribute to the selection of the right equipment. By understanding material compatibility, work area size, resolution, software compatibility, safety features, and budget, you can choose a laser engraving machine that perfectly suits your needs.

Embrace this cutting-edge technology and watch your creativity come to life in stunning detail. The possibilities with laser engraving machines are vast, and the journey toward precision artistry is just beginning.